WIN-WIN Waterjet Dual Head Cutting Machine: Empowering Middle East Manufacturing with Precision and Efficiency

1. Global Industry Leader: WIN-WIN’s Market Influence in Middle East

In the dynamic and competitive landscape of global industrial cutting technology, the Waterjet Dual head cutting machine has emerged as a revolutionary game-changer, particularly for high-volume, precision-focused manufacturing sectors that demand both speed and accuracy. As a leading global provider of waterjet cutting solutions, WIN-WIN boasts extensive production bases spanning multiple continents, mature supply chains that ensure stable component sourcing, and a broad international footprint covering key markets in Asia, Europe, and the Middle East. With decades of industry experience, the company has consistently pushed the boundaries of innovation, investing heavily in R&D to upgrade product performance and meet the evolving needs of clients worldwide. Recently, WIN-WIN secured a notable order from a prominent Middle Eastern manufacturer—an industry giant in metal fabrication and infrastructure projects—who purchased two sets of dual Z-axis Waterjet Dual head cutting machine in one go. This collaboration not only underscores the strong market demand for WIN-WIN’s high-quality products in the Middle East but also reflects the deep trust that large-scale manufacturers place in a globally recognized brand with a proven track record. Against the backdrop of the Middle East’s booming industrial sector, driven by strategic initiatives like Saudi Arabia’s Vision 2030 which fuels robust growth in automotive, aerospace, and construction industries, the Waterjet Dual head cutting machine has become an indispensable tool for manufacturers striving to enhance productivity, precision, and market competitiveness.

2. Customized Solutions: Aligning Aesthetics with Performance

The Middle Eastern client, a key player in metal fabrication and high-end architectural stone processing, imposed stringent requirements on cutting equipment: it must handle a wide range of materials—from heavy-gauge steel to fragile natural stone—while maintaining exceptional accuracy within microns. After an extensive six-month evaluation of global suppliers, comparing technical parameters, after-sales service, and cost-effectiveness, the client ultimately chose WIN-WIN’sWaterjet Dual head cutting machine. The decision was driven by the equipment’s advanced dual Z-axis design, which enables independent height adjustment for each cutting head, robust performance even in continuous 24/7 operation, and the brand’s unwavering reputation for reliability built on years of delivering consistent results. Beyond core performance metrics, the client expressed a unique desire for personalized aesthetics to align the equipment with their factory’s modern brand identity, including a custom color scheme and logo engraving. As a large-scale manufacturer with flexible customization capabilities, WIN-WIN’s engineering and design team worked closely with the client through multiple iterations, tailoring every detail to meet their needs. This meticulous attention to detail—seamlessly blending industrial functionality with visual personalization—set WIN-WIN apart from competitors who offered only standard models. The customized Waterjet Dual head cutting machine not only delivers outstanding performance but also serves as a reflection of the client’s brand image, making it a standout addition to their state-of-the-art production facility.

3. Efficient Delivery: Backed by Strong Production Capabilities

In the fast-paced industrial sector, delivery speed directly impacts production schedules, project deadlines, and ultimately market competitiveness. Recognizing the client’s urgent need to expand production capacity to fulfill a large-scale infrastructure contract, WIN-WIN committed to an accelerated timeline, completing the entire process of manufacturing, precision assembly, and rigorous testing of the two Waterjet Dual head cutting machine in just one month—a feat that exceeds industry standards by nearly 50% for similar complex equipment. This remarkable efficiency is attributed to WIN-WIN’s large-scale integrated supply chain management, which minimizes lead times for key components, advanced automated production facilities that reduce manual errors and speed up assembly, and in-house R&D capabilities that allow for seamless coordination between design, production, and quality control teams. Each Waterjet Dual head cutting machine underwent a series of strict tests, including precision calibration using laser measurement tools, load-bearing performance under maximum pressure, and dual Z-axis synchronization checks to ensure perfect coordination. These rigorous procedures guarantee compliance with international quality standards (ISO 9001) and the client’s specific requirements. The client praised WIN-WIN’s responsiveness, stating, “The rapid delivery of the high-qualityWaterjet Dual head cutting machine has enabled us to accelerate our production timeline without compromising on quality, a testament to WIN-WIN’s professional expertise and manufacturing strength.”

4. Versatile Applications: Adapting to Diverse Industrial Needs

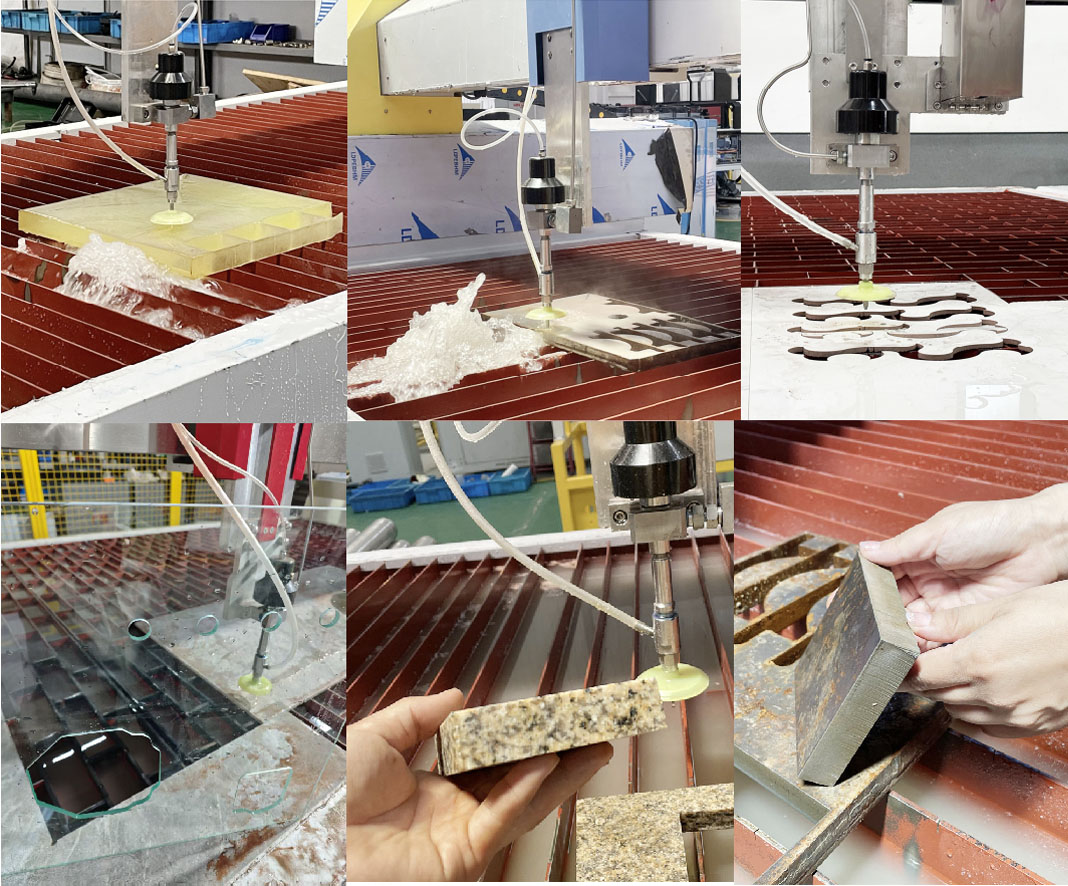

The Waterjet Dual head cutting machine boasts exceptional versatility, making it suitable for a wide range of applications across multiple industries— a key advantage that deeply resonated with the Middle Eastern client’s diverse processing needs. In the metal fabrication sector, the machine excels at cutting various metals, from carbon steel and stainless steel used in construction to high-strength titanium alloys and aluminum composites for aerospace components. Its cold-cutting technology, which uses ultra-high-pressure water mixed with abrasive particles, eliminates heat-affected zones entirely, ensuring no material warping, structural damage, or changes in material properties— a critical feature for high-precision parts. In the construction and architectural industry, the machine is ideal for processing stone, glass, and ceramic materials, enabling intricate designs such as custom mosaic patterns, curved stone facades, and decorative glass panels with smooth, burr-free edges that require no secondary polishing. Additionally, the Waterjet Dual head cutting machine is widely used in electronics and composite material processing, where its non-contact cutting method protects delicate materials like carbon fiber sheets and smartphone components from thermal or mechanical damage. Whether handling large-scale batch production of 10,000+ metal parts or custom precision cutting for one-of-a-kind architectural pieces, the Waterjet Dual head cutting machine adapts seamlessly to different materials and process requirements, solidifying its position as a multi-purpose, cost-effective cutting solution.

5. Optimized Pump Configuration: Achieving Performance-Efficiency Balance

To maximize performance, WIN-WIN paired the two machines with one

SL-VI 50HP PLUS dual intensifier pump—an optimized configuration verified by practice. Unlike single-intensifier pumps, it operates both intensifiers simultaneously, delivering 4136 bar (60,000 psi) pressure and 6.5 L/min flow. This ensures stable power for two full-load machines, avoiding pressure fluctuations and batch quality issues. The rational matching minimizes energy waste and maximizes productivity, creating long-term value.

6. Conclusion: Leading the Future of Waterjet Cutting Technology

In conclusion, WIN-WIN’s Waterjet Dual head cutting machine stands out as a leader in the global waterjet cutting industry, combining innovative design, exceptional performance, and flexible customization to meet the diverse needs of international clients. As a large-scale waterjet equipment manufacturer with rich experience, strong technical strength, and a global footprint, WIN-WIN’s successful delivery to the Middle Eastern client— featuring customized aesthetics, rapid turnaround, and an optimized pump configuration— showcases its ability to deliver end-to-end solutions that drive operational excellence. The Waterjet Dual head cutting machine not only addresses the immediate needs of manufacturers for speed, precision, and cost savings but also adapts to future trends in sustainable and intelligent manufacturing. As the demand for precision cutting technologies continues to grow across the Middle East and beyond, fueled by infrastructure development and industrial upgrading, theWaterjet Dual head cutting machine is poised to play a pivotal role in shaping the future of industrial manufacturing, helping businesses achieve new heights of efficiency, precision, and sustainability. WIN-WIN remains committed to innovation and customer satisfaction, continuing to set new standards in the global waterjet cutting industry.